We have manufactured precision components by fully utilizing the latest technologies and high-precision equipment. Thus, we have flexibly responded to customers' requests and worked on innovative projects.

TECHNOLOGY

Technologies and equipmentWe have manufactured precision components by fully utilizing the latest technologies and high-precision equipment. Thus, we have flexibly responded to customers' requests and worked on innovative projects.

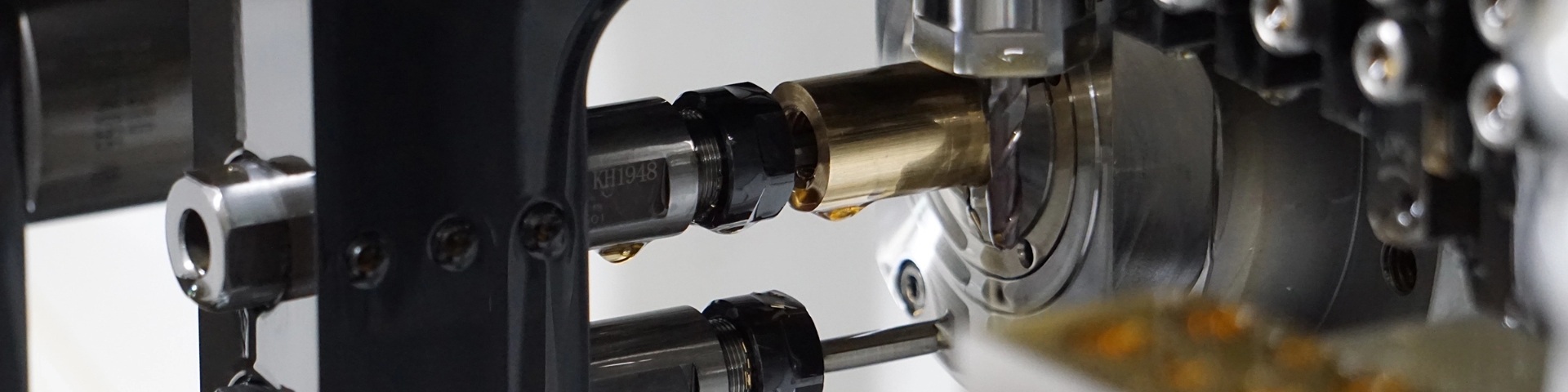

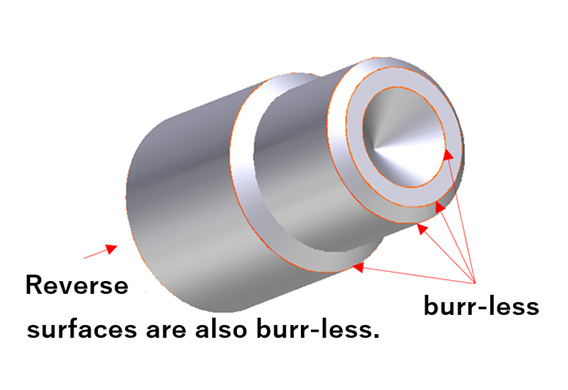

Nishida Precision can perform burr-less machining of minute components, leaving almost no burrs on each edge.

The burr height after machining is kept to no more than 5 µm.

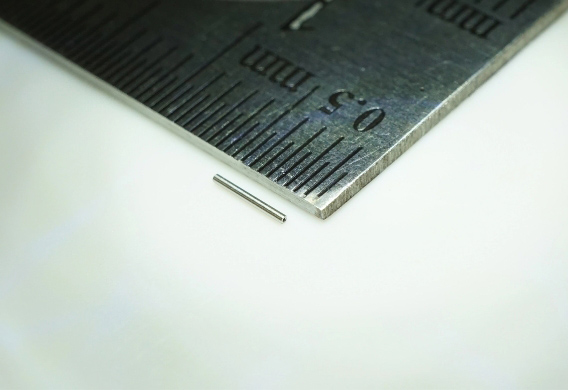

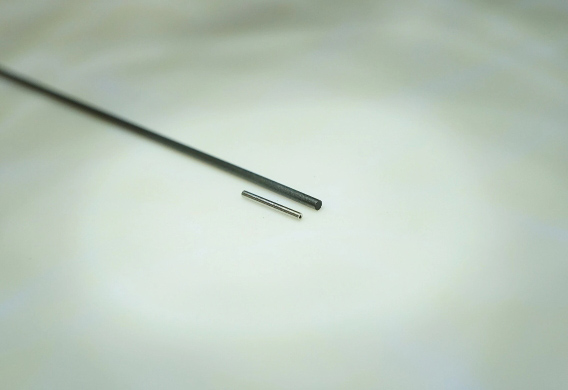

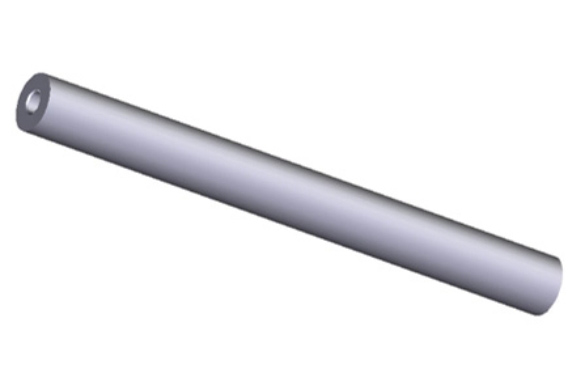

Nishida Precision can drill a hole with an ultra-small diameter of φ 0.15 mm.

We can also conduct small-diameter deep hole processing with hole depth (L)/hole diameter (D) ≥ 25.

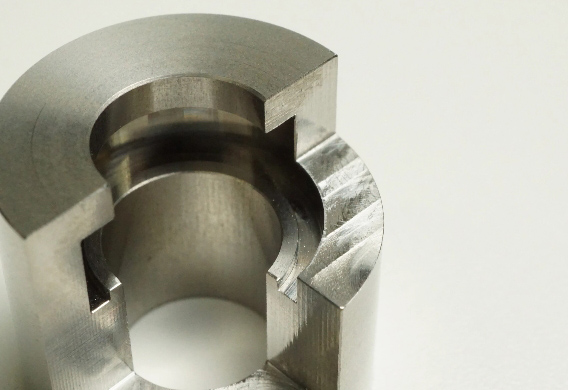

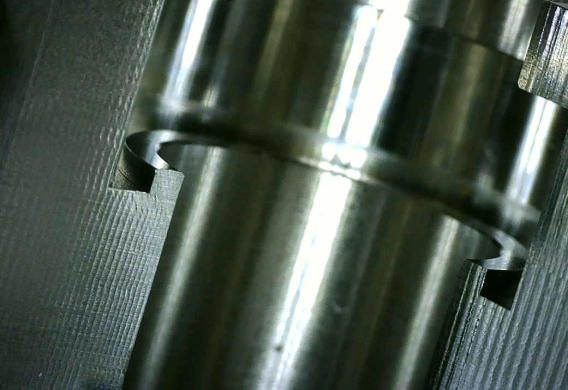

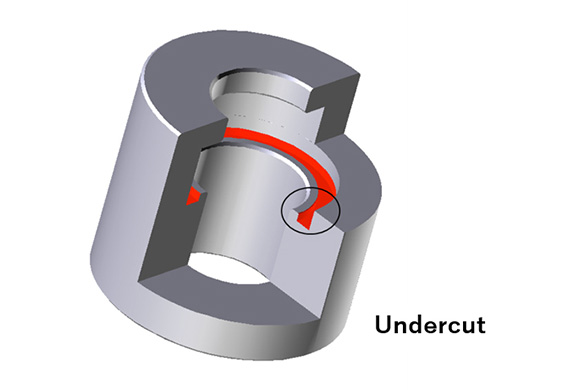

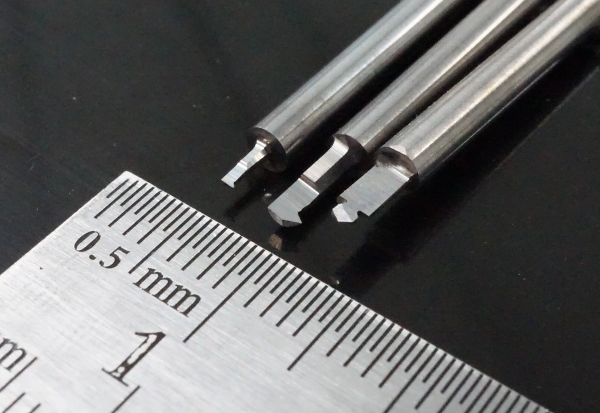

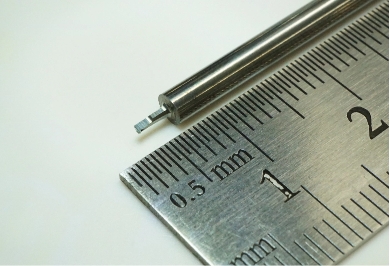

End face grooves inside inner diameter grooves can be machined by undercutting.

Using tools manufactured in-house, we handle the shapes that cannot be achieved with commercially available tools, so we can deliver a prototype component within a short period of time.

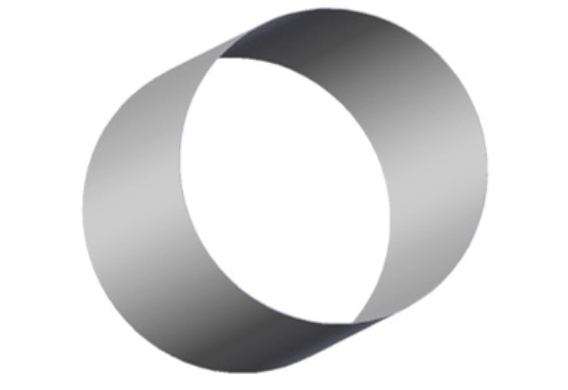

Thin walls with 0.04 mm ± 0.01 per side can be machined.

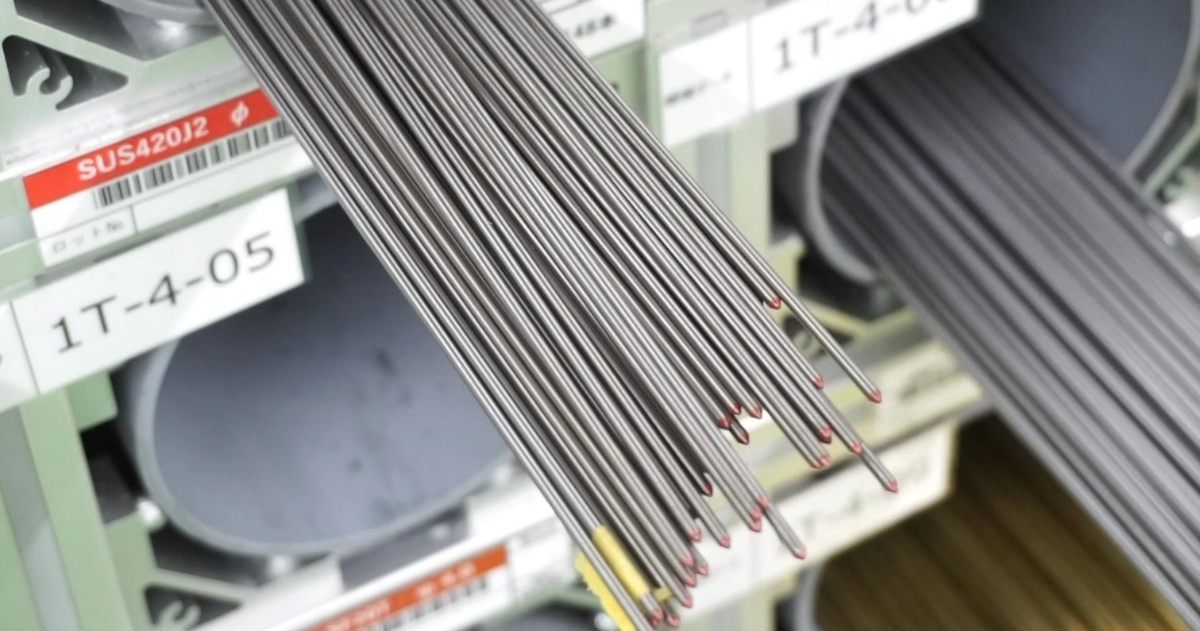

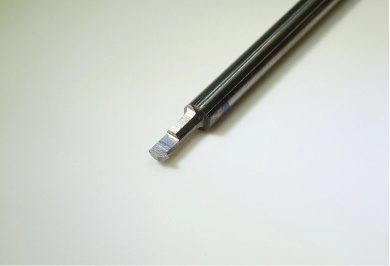

Nishida Precision manufactures its own cutting tools for shapes that cannot be achieved with commercially available cutting tools. Therefore, we can handle complex shapes and deliver a prototype component within a short period of time.

Also, we have improved the quality level by in-house manufacturing a cutting tool that is suitable for each product. We currently manufacture around 2,000 types of cutting tool, and among them, approximately 300 are original cutting tools made in-house. Nishida Precision has been manufacturing cutting tools since our company was founded, and it can be said that our high-precision machining originates in the manufacturing of cutting tools.

Since even the slightest difference in the cutting edge angle is directly linked to machining quality and improvements in product accuracy, skilled craftsmanship is required for manufacturing cutting tools. Nishida Precision’s strengths include our creative ability to devise cutting tools for higher precision machining, to say nothing of our cutting tool polishing technology that has been passed on since the foundation.

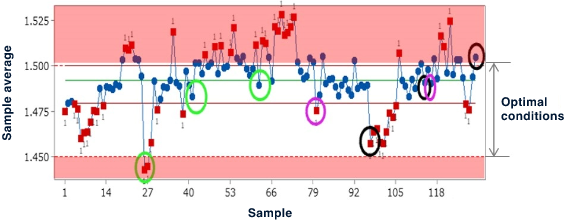

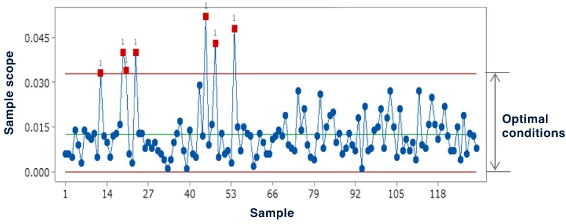

In order to optimize machining equipment cutting conditions, such as the spindle speed and cutting tool mounting angle, we perform trial machining using setup samples.

We measure sample dimensions, and visualize machining with control charts (X-bar, R control charts, etc.) to determine optimal conditions.

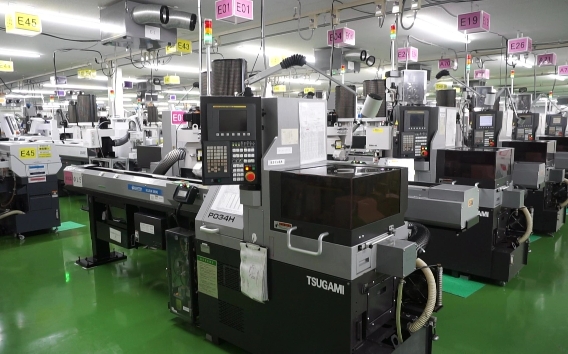

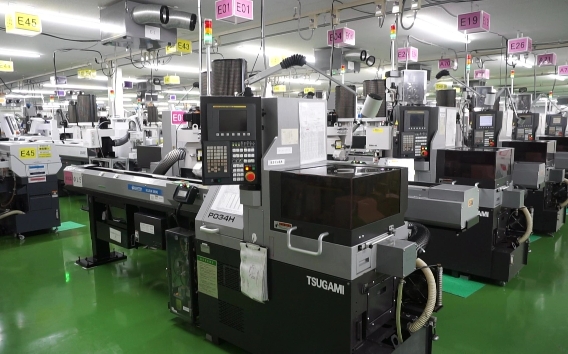

| No. | Manufacturer name | Model | Qty |

|---|---|---|---|

| 1 | TSUGAMI | P034 | 13 |

| 2 | TSUGAMI | P03 | 2 |

| 3 | CITIZEN | R04 | 16 |

| 4 | TSUGAMI | B007 | 10 |

| 5 | CITIZEN | L10 | 6 |

| 6 | CITIZEN | L12 | 11 |

| 7 | CITIZEN | B12 | 2 |

| 8 | TSUGAMI | B0125 | 18 |

| 9 | TSUGAMI | B0126 | 3 |

| 10 | TSUGAMI | BS12 | 18 |

| 11 | CITIZEN | K12 | 6 |

| 12 | CITIZEN | M16 | 2 |

| 13 | CITIZEN | L16 | 1 |

| 14 | CITIZEN | E16J | 1 |

| 15 | TSUGAMI | BE18 | 4 |

| 16 | CITIZEN | M20 | 9 |

| 17 | CITIZEN | L20 | 5 |

| 18 | TSUGAMI | BS20 | 1 |

| 19 | TSUGAMI | BU20 | 4 |

| 20 | TSUGAMI | B0205 | 2 |

| 21 | CITIZEN | L32 | 2 |

| 22 | CITIZEN | M32 | 12 |

| 23 | CITIZEN | BNE-51SY6 | 1 |

| 24 | TSUGAMI | P05 | 3 |

| Total | 152 | ||

CITIZEN R04

CITIZEN R04

CITIZEN M32

CITIZEN M32

| No. | Manufacturer name | Model | Qty |

|---|---|---|---|

| 1 | DMG MORI Co., Ltd. | NTX1000 | 1 |

DMG MORI Co., Ltd. NTX1000

DMG MORI Co., Ltd. NTX1000

| No. | Equipment name | Qty |

|---|---|---|

| 1 | Compact CNC lathes | 4 |

| 2 | General-purpose milling cutters | 5 |

| 3 | General-purpose lathes | 2 |

| 4 | Bench lathes | 12 |

| 5 | Bench drilling machines | 4 |

| 6 | Super-hard tool grinders | 15 |

| 7 | Ultrasonic deburring machine Blue Star R&D | 1 |

| 8 | Barrel finishing machine | 3 |

| 9 | Airblast | 1 |

Ultrasonic deburring machine Blue Star R&D MARS-DB-20-4800

Ultrasonic deburring machine Blue Star R&D MARS-DB-20-4800

| No. | Equipment name | Manufacturer name | Model | Qty |

|---|---|---|---|---|

| 1 | CNC image measurement system | Nikon Corporation | NEXIV VMZ-R3020 | 1 |

| 2 | In-line projection image measuring instrument | KEYENCE CORPORATION | TM-X5006 | 2 |

| 3 | In-line projection image measuring instrument | KEYENCE CORPORATION | TM-X5040 | 2 |

| 4 | Image size measurement system | KEYENCE CORPORATION | IM-6225 | 1 |

| 5 | 3D image size measurement system | KEYENCE CORPORATION | LM-X100TL | 3 |

Nikon Corporation NEXIV VMZ-R3020

Nikon Corporation NEXIV VMZ-R3020

Please feel free to contact us if you require consultation

or have any questions.

MAIL FORM

Headquarters+81-241-45-3432

Aizuwakamatsu Plant+81-242-76-0123