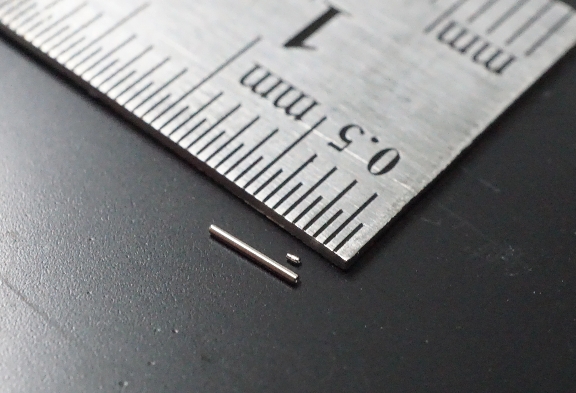

We have contributed to the development of medical equipment, semiconductor equipment, etc. and have provided advanced precision components. We have valued the cooperative relationship with our customers from prototype manufacture through mass production.